Features & Details

- With a 50-ton lifting capacity, our hydraulic press helps you easily disassemble and install car bushings, ball joints, universal joints, and more, as well as straighten, bend, and punch metal parts. Whether you're a professional or an enthusiastic DIY auto repair enthusiast, the press offers quick and easy operation.

- Hydraulic and pneumatic: This hydraulic workshop press features a pneumatic auxiliary pump that can be quickly connected to an air compressor for easier operation. It includes a safety control valve to prevent overloading and protect against bending or damage.

- Adjustable Height: The hydraulic workshop press's worktable features a quick-adjust winch and pin system with 7 height settings from 83-983 mm (3.3 to 38.7 in), allowing for flexible working positions. The cylinder stroke is 185 mm (7.3 in). Note: Exceeding the cylinder stroke range may damage the cylinder seals.

- Triangular base reinforcement: The triangular structure of the hydraulic workshop press, enhanced with a triangular brace, significantly improves base stability. Combined with the H-shaped frame, this ensures the press remains stable and wobble-free when attaching components.

- Robust construction: This structure, made of thick steel, offers improved load-bearing capacity and durability. The large-diameter pressure column is designed to minimize slippage and ensure stability and long-lasting performance even under heavy loads.

Frequently Bought Together

Reviews 5.0

All reviews are from verified purchases

Average rating based on 5 reviews

About this item

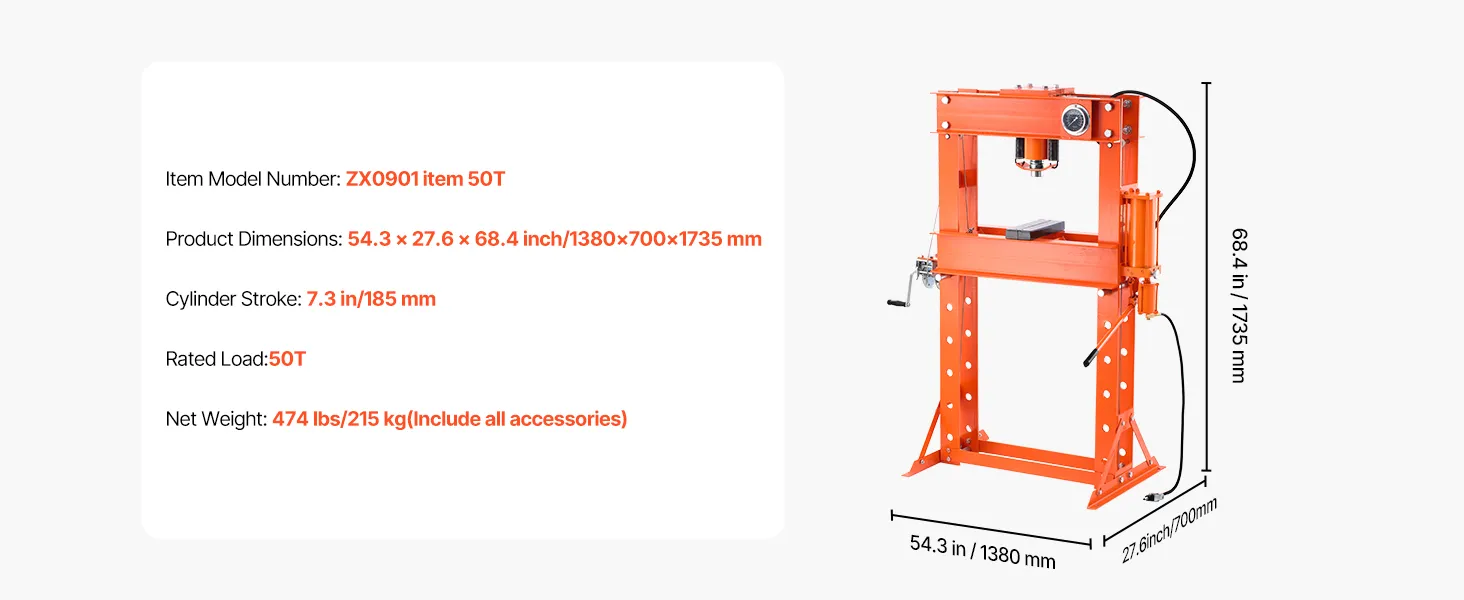

- Article model number

- ZX0901 Article 50T

- Product size

- 54.3 x 31.5 x 68.4 inches / 1380 x 800 x 1735 mm

- Cylinder stroke

- 7.3 inches / 185 mm

- Rated load

- 50 t

- Operating pressure of the hydraulic pump

- 0.8–1.2 MPa

- Hydraulic oil model

- 15#

- Net weight

- 474 lbs / 215 kg (including all accessories)

VEVOR Hydraulic Pressing Machine – Perfect for Auto Repairs and Metal Work

The VEVOR hydraulic press machine has a 50-ton capacity. It can easily bend, straighten, and press car parts and metal pieces. The press has a pneumatic assist pump that connects to an air compressor. The work table can be adjusted to different heights. This makes it flexible for a range of tasks and materials. It has an H-frame with triangular-shaped bases. This makes the press very stable and durable, even under heavy loads.

Hydraulic Pressing Machine 50-Ton Capacity Handles Heavy Work

Working on cars and metal parts can be hard without the right tools. A hydraulic press makes repairs faster and easier. It gives you the power to handle tough jobs at a workshop or at home. Our VEVOR machine provides 50 tons (100,000 lbs) of pressure for heavy-duty work. The 50-ton hydraulic shop press has a high load capacity, making it easy to handle heavy weights.

With a pneumatic h-frame shop press, U-joints can be removed and replaced without damaging nearby parts. A hydraulic press can also straighten bent metal parts. You can create bends in metal at the exact angle you want. Finally, a hydraulic press lets you stamp patterns or shapes into metal. Using this press makes automotive repairs quicker and easier. You no longer have to struggle with stuck parts in your garage.

Air Compressor Powers Pneumatic Assist

The hydraulic shop press features pneumatic assist. The air compressor powers the hydraulic pump through a pneumatic connection. This makes it easy to connect and set up quickly. The compressed air lets the operator do less manual pumping. It also takes less effort to run the pump with the adjustable hydraulic press for automotive repair.

The operator can use the hydraulic pump without having to pump it by hand. The pneumatic assist has a regulator valve to stop overloading the press. This prevents problems caused by excessive force, which could bend or damage the press. With a heavy-duty garage hydraulic press, the pneumatic assist helps the operator work efficiently.

Seven Height Settings for Maximum Flexibility

The work table can be quickly adjusted using a winch and pin-and-lift system. This lets you set the table to 7 different heights for different jobs with the 50-ton hydraulic shop press. The lowest position gives 3.3 inches (83 mm) of clearance. The highest position gives 38.7 inches (983 mm) of clearance. This makes 7 total height settings.

This flexibility makes the press work for a variety of tasks. The cylinder has a 7.3-inch (185 mm) stroke for vertical pressing. Always stay within the cylinder stroke range. Exceeding it can damage seals, cause leaks, and reduce oil system pressure. The pneumatic h-frame shop press makes height adjustments smooth and safe for different jobs.

Hydraulic Pressing Machine Triangular Brace Increases Base Stability

The base features a triangular brace for added strength and stability. It also evenly distributes the downward force. The triangular shape makes the heavy-duty garage hydraulic press very stable while in use. The H-shaped support adds more strength to the frame. Together, they make the press very rigid. This keeps the working platform level for all pressing jobs.

Using an adjustable hydraulic press for automotive repair, you can work on parts safely and precisely. The press frames do not move when using high pressure. This combination makes pressing work pieces accurate.

Hydraulic Pressing Machine Thickened Steel Frame Lasts for Decades

The 50-ton hydraulic shop press is made from the thickest type of steel available. This strong design can support up to 50 tons of weight even with repeated use. Very little wear happens from daily use over many years. Because the press is so durable, it is expected to last for a long time. The large-diameter pressure column is built to handle bending forces.

The extra-thick pneumatic h-frame shop press column prevents slippage during use. This keeps all parts in their correct position during operation. The heavy-duty construction can handle repeated heavy use for many years.

Handles Bushings, Bearings, and Press-Fit Parts

Bushings come out clean and don’t get damaged. New bushings go in straight and lined up every time. Wheel bearings can be removed and put back safely using the adjustable hydraulic press for automotive repair. Press-fit parts come apart without breaking anything. Gears press onto shafts with the right amount of force. This stops cracking or bending. You can get professional results with controlled force with the heavy-duty garage hydraulic press.

Perfect Choice for Professional Shops and Home Garages

Hydraulic presses are standard in car repair shops. They are often used to press bearings out of a cleaned brake drum. They are also used to install bearings into a hub with the adjustable hydraulic press for automotive repair. Many DIY mechanics save money by doing their own repairs instead of paying for shop labor.

Having a hydraulic press lets DIYers tackle bigger car projects at home on the weekend. Minor engine repairs are more straightforward with the 50-ton hydraulic shop press. Using a press helps you learn more about mechanical parts. It also enables you to do better home repairs.

Questions and Answers (0)

VEVOR hydraulic workshop press 20 t (H-frame) with press plate, adjustable hydraulic press (max. cylinder 185 mm) with triangular support, suitable for bending, straightening & punching, orange